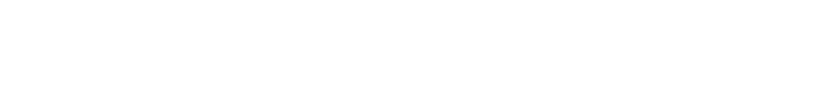

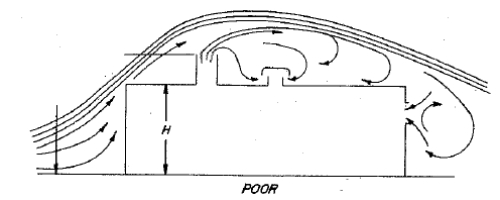

The Air Quality & Climate Division (AQCD) requires that emissions from most regulated air pollution sources exhaust through an unobstructed, vertical stack of sufficient height to ensure appropriate upward dispersion of the exhaust, thus minimizing the ground level concentration of air pollutants where individuals may be exposed. An unobstructed vertical stack is crucial to ensure the velocity momentum of the exhaust exiting the stack, as well as any exhaust heat induced buoyancy, may optimally disperse the pollutants upward. Stack obstructions such as the older “conventional” style rain caps, as well as horizontal stack discharges, restrict upward velocity momentum and reduce potential buoyancy dispersion and can increase ground level exposure to pollutants in the exhaust. A sufficient stack height is also necessary to ensure the upward dispersion of the exhaust is not adversely affected by the wind blowing over its own building or nearby buildings that can entrap the exhaust in eddies and the downwind building cavity and wake areas. Such downwash of the exhaust can significantly increase ground level concentrations of pollutants and pull the contaminated air back into the building through air intakes, windows and doors. These factors all must be considered when selecting an appropriate rain guard and stack height. The AQCD may require any regulated facility to increase the stack height, remove a rain cap, or conduct an air quality impact dispersion analysis to verify compliance with ambient air quality standards for any stack at a facility if, in its judgment, adequate dispersion cannot be maintained with the current stack configuration.

Stack Height Guidance

Following the use of effective emission controls, an adequate exhaust stack height is the next most important focus to ensure adequate dispersion of the exhaust to minimize the ground level concentration of air pollutants where individuals may be exposed. Larger air pollution emission sources generally require a taller stack that is often established as part of the permit review process that may include an air quality impact dispersion analysis . But even smaller emissions sources, including sources of more toxic pollutants, should be constructed with a sufficient stack height to minimize the entrapment of the exhaust in the cavity and wake regions on the downwind side of the building, referred to as downwash. At a minimum, the AQCD recommends all stacks for regulated emission points be at least four feet above the roof and that they not be equipped with any device that may obstruct the upward dispersion of the exhaust such as an old style rain cap. You should consult with your heating & ventilation contractor to determine the applicability of any other codes that may apply to your specific stack situation that may impose further minimum stack requirements such as the International Building Codes (IBC), National Fire Protection Association codes (NFPA) or the US Occupational Safety and Health Administration (OSHA).

General Stack Height Design Guidelines: Good air pollution control engineering practice (GEP) for stack heights is conservatively calculated with the following formula, which may be simplified in most cases to 2.5 times the building height. At this height the aerodynamic effects of the adjacent buildings are no longer considered to adversely affect the exhaust plume and downwash is not expected to occur. It is desired air pollution control practice to minimize this pollution concentrating effect of downwash. It is important to note that while GEP is the optimum stack height at which building influences on dispersion are eliminated, this can result in a taller stack than practical in many cases. Downwash influences may still be reduced with shorter stacks but the potential ground-level impacts will increase with successively lower stacks. It should also be noted that there is no air pollution engineering justification for constructing a stack greater than GEP and no credit can be taken in an air quality impact evaluation for stack height in excess of GEP. If ground-level impacts are still of concern then further emission reduction measures, rather than dilution, should be employed.

HGEP=H+1.5L

Where:

HGEP = good engineering practice stack height, measured from the ground-level elevation at the base of the stack.

H = height of “nearby” structures measured from the ground-level elevation at the base of the stack. This is most often simply the height of the building housing the stack.

L = the lesser dimension, height or projected width, of the “nearby” structure. For most buildings other than high rises the height of the building is the lesser of the two dimensions.

nearby = structures are considered to be “nearby” if they are located within five times the lesser of the height or projected width of the structure to the stack. For most buildings the height of the building is the lesser of the two dimensions

Further guidance on GEP stack height may be found in the US EPA document, Guideline for Determination of Good Engineering Practice Stack Height (Technical Support Document for the Stack Height Regulations), Revised, June 1985 (EPA-450/4-80-023R).

Modification of Existing Stacks: A facility should consult with the AQCD prior to making any modifications to an existing permitted stack that may adversely affect ground level air quality such as a lowering of the stack height, relocation of the stack nearer to potential structures of influence, or decreases in exhaust exit velocity such as through installation of a smaller exhaust fan or an increase in the stack diameter.

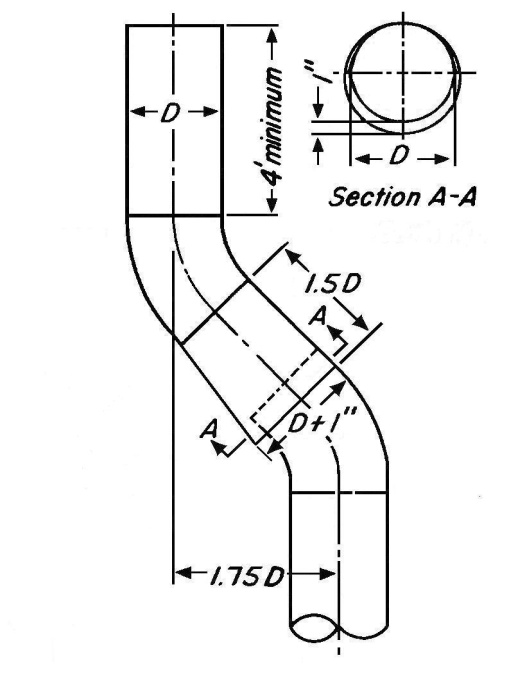

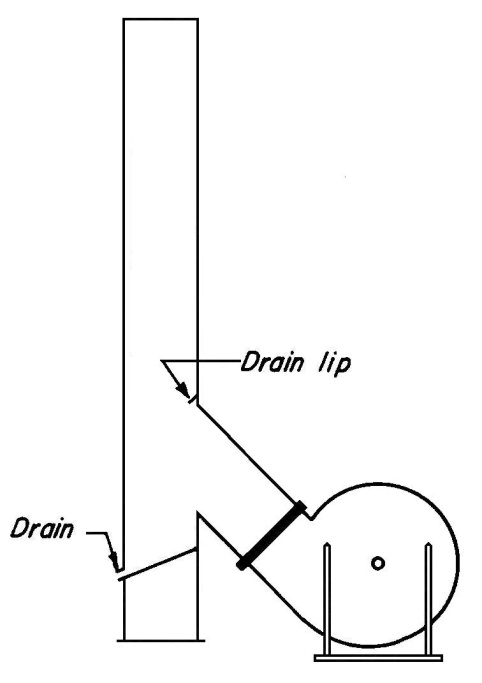

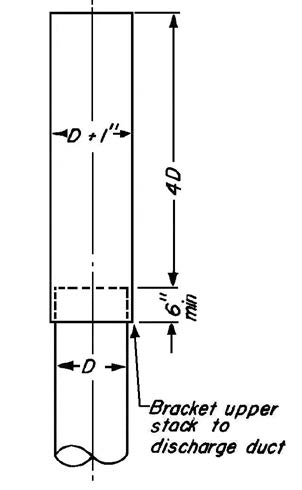

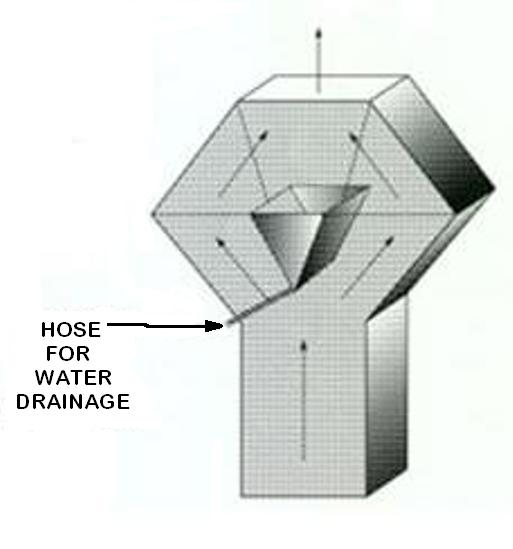

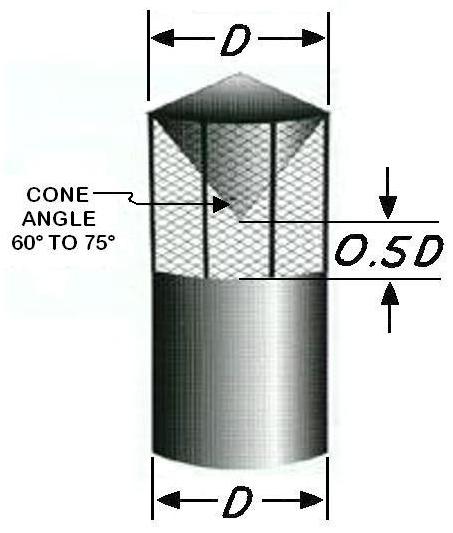

Rain Guard Guidance

While rain guards are often necessary in our climate to protect certain equipment from rain entering a stack, there are acceptable and unacceptable designs. Rain caps installed on stacks must allow for unobstructed, vertical flow of the exhaust. Examples of preferred, acceptable and unacceptable rain guard and stack configurations are shown below. Alternative configurations may be submitted to the AQCD for approval prior to construction and installation.

Preferred Configurations

Acceptable Configurations:

Unacceptable Configurations: